Surface treatment plays an important role in various fields of manufacturing such as the automotive, household appliance, building and packaging industries.

Using continuous coating techniques such as, for example, galvanic coating or hot-dip, foil and paint coating of aluminium and steel strip, it is possible to produce surfaces that improve the usability and corrosion resistance of the sheet material decisively. The different types of coatings are also growing thinner and more effective with ever more complex layer structures.

Users expect not only excellent processing properties and usage characteristics, but also high life time, long-term value and high quality from modern materials.

With increasing demands on coating quality, the responsibility of the manufacturing industries has grown immensely. Rising expectations regarding quality and savings in raw materials necessitate a maximum in the precision and operational reliability of measuring equipment.

To meet the high demands, the steel industry needs innovative and accurate online measuring technology with intelligent quality management and evaluation systems.

The measuring processes and technologies described in this brochure are, together with optimized process models, precision control loops and appropriate regulating elements, the prime pre-requisites for achieving the high level of product quality required from high-speed continuous production processes.

Maximum availability and reproducible measuring results ensure the high process stability required for continuous operation.

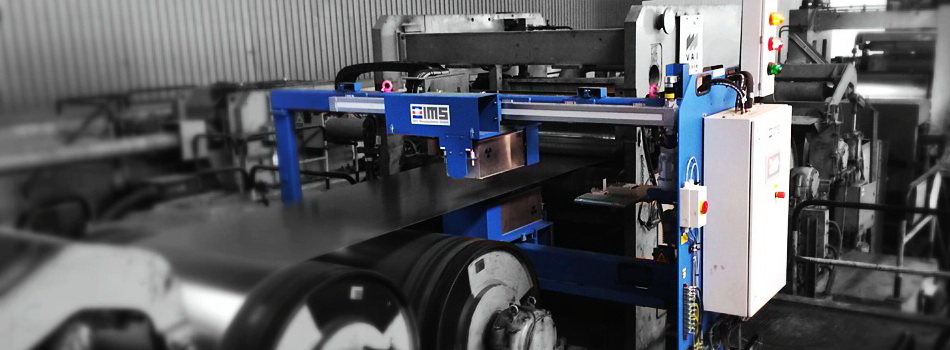

IMS Coating Weight Gauges in:

-

Hot-Dip Galvanizing Line

-

Color Coating Lines

-

Electrolytic Tinning Line