The core element of hpl slitting shears is the knife shaft. All knife shafts are manufactured entirely in-house, enabling them to offer their customers unsurpassed quality:

-

Highest precision of the knife shaft bearing

-

Lower knife shaft infinitely variable in axial direction

-

Knife shaft adjustment by servomotor via low-backlash, pre stressed ball screws

-

Automatic opening and closing of the front shear housing part of standard equipment

-

Extremely high concentricity and plane parallelism

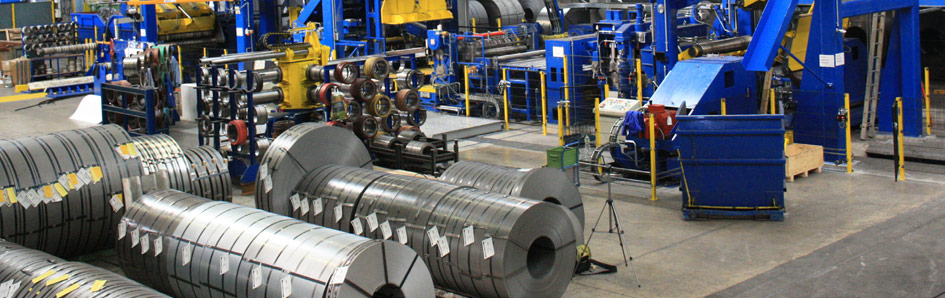

The high degree of precision in hpl slitting shears enables line

speeds of up to 1,000 m / min at constant quality.

Their new development in the cut-to-length product range is called

flying cross-cut shears. This kind of shears avoids stopping the strip

during the cross-cut process, thus allowing a continuous line

operation and a corresponding productivity increase.

Each line is individually planned and designed based on the conditions on site and the product mix of the customer.

These customer specific line concepts include:

-

Loop pits, braking units and recoilers

-

Direct strip spooling, incl. guide mechanism (starting from 1 up to required number of recoilers)

-

Alternating recoiling of single strips, incl. guide mechanism (starting from 1 up to required number of recoilers)

For more information please visit:

www.hpl-neugnadenfelder.de